Products

Optimized & Industry-ready Solutions

For All Your Needs

We supply certified European-grade stainless-steel products engineered for demanding marine, offshore, automotive and industrial applications.

Our focus: precision, durability and consistent performance under harsh conditions.

Our Innovations

Industry Focused Products!

Stainless Steel Precision Strips

Our stainless-steel precision strips are engineered for demanding marine, offshore, automotive and industrial environments.

We deliver tight dimensional tolerances, smooth surface finishes and consistent European-grade quality.

Available Grades

AISI 304, 316, 316L, 309, 310, 301, 420, 904L

Thickness Range

0.05 mm – 3.00 mm

(We can go even lower than 0.05 mm depending on grade and temper.)

Width Range

5 mm – 1500 mm

Surface Finishes

2B

BA / Bright Annealed

1D / Hot rolled

Polished & brushed (on request)

Deburred or fully rounded edges

Mechanical Properties (Typical)

Tensile strength: 650 – 1700 MPa

Soft annealed, half-hard, hard, and extra-hardened tempers

High corrosion resistance

Excellent formability and spring properties (301/304/316)

Dimensional Tolerances

Width tolerance: ±0.05 – ±0.20 mm

Thickness tolerance: according to EN 10258 precision strip standards

Edge condition: slit, deburred, safe-edge or rounded

Applications

Shipbuilding • Cable management • Subsea systems • Industrial machinery • Automotive brackets • Engineered components • Electrical systems • Fabrication & assembly

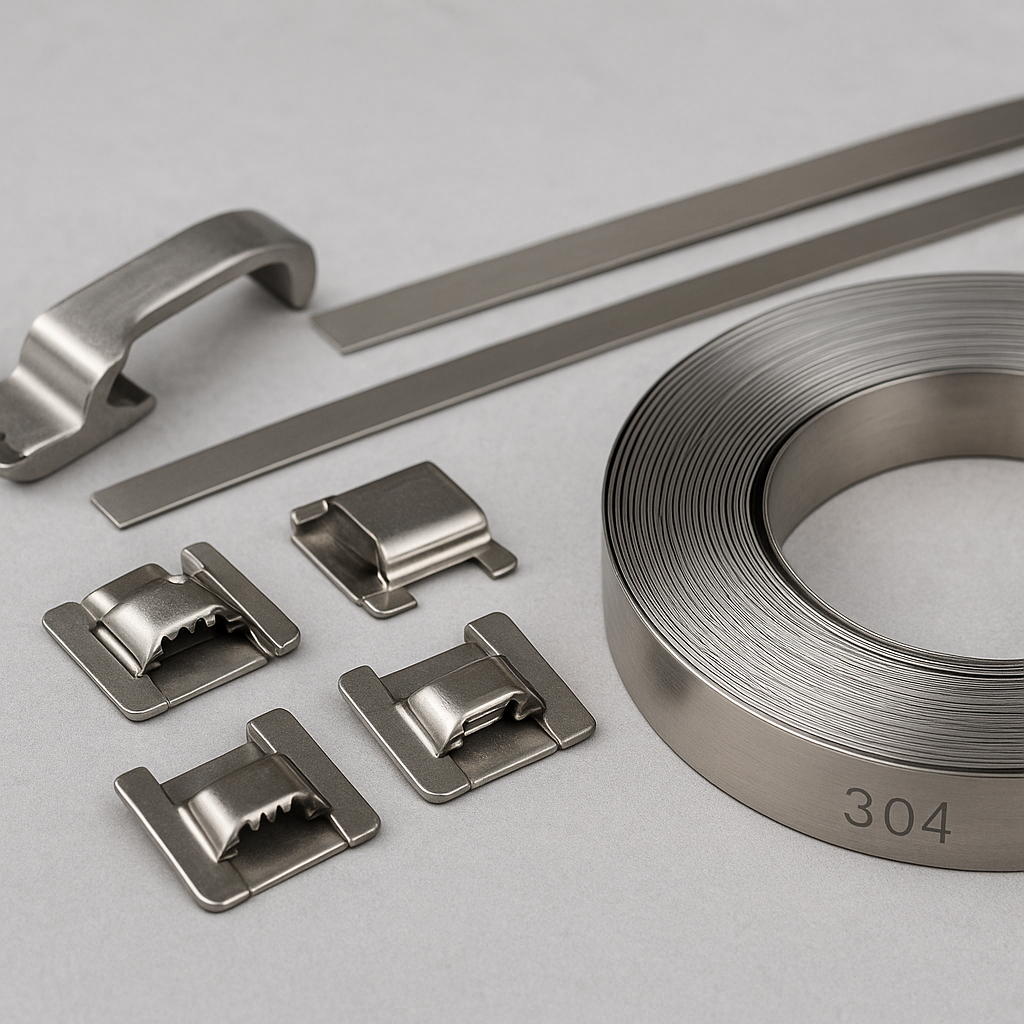

Marine-Grade Stainless-Steel Banding Systems

Premium corrosion-resistant stainless-steel banding engineered for demanding marine, offshore and coastal environments.

Designed for maximum durability in saltwater, high-chloride areas, UV exposure and harsh outdoor conditions.

Available Grades

AISI 304, 316, 316L, 309, 310, 904L, 301, 201, 430

(316/316L/904L recommended for heavy saltwater and offshore use)

Thickness Range

0.10 mm – 6.00 mm

(Custom gauges available for special applications)

Width Range

4.6 mm – 32 mm

(Standard widths for banding tools, buckles and pole-mounting systems)

Mechanical Properties

Tensile strength: 550 – 1100 MPa (depending on grade + temper)

High flexibility for tight loops and high-tension fastening

Exceptional resistance to chloride corrosion, vibration and outdoor fatigue

Suitable for extreme temperatures (309/310 high-heat alloys)

Surface Finishes

Bright Annealed (BA)

Smooth / matte banding finish

Rounded, deburred or safe-edge options

Applications

Offshore platforms & shipbuilding

Subsea equipment, pipelines & cable restraint

Coastal infrastructure & port installations

Telecom towers, CCTV poles & fiber-optic installations

Electrical utility poles & industrial cable routing

Marine structures, buoys, navigation systems

Benefits

Long-term performance in saltwater & coastal climates

High tensile strength for reliable fastening

Fully compatible with industry-standard banding tools & buckles

European-grade stainless steel

Suitable for marine, offshore, industrial, telecom, energy & infrastructure sectors

Banding Buckles & Accessories

A complete range of high-strength stainless-steel buckles, clips and fastening accessories engineered for maximum reliability in harsh environments.

Designed for secure fastening in marine, offshore, telecom, utility, electrical and industrial installations.

Available Grades: AISI 304, 316, 316L, 301, 309, 310, 430, 904L

(316/316L/904L for saltwater; 309/310 for high-temperature environments)

Width Compatibility: Fits all standard banding widths 4.6 mm – 32 mm

Compatible with: smooth banding, embossed banding, pole-mount systems.

Mechanical Performance:

• Tensile strength: 550 – 1100 MPa (depending on grade)

• Vibration-resistant locking performance

• Excellent chloride-corrosion resistance for coastal & offshore use

• Long service life in UV, salt, humidity and extreme temperatures

Applications:

Energy infrastructure • Telecom towers • Fiber-optic installations • Marine structures • Offshore platforms • Industrial cable management • Electrical poles • Traffic & city infrastructure • HVAC & mechanical systems

High-Tolerance Engineered Materials

Custom stainless-steel materials processed to exacting dimensional and mechanical specifications for demanding industries.

Engineered for precision-critical applications where tolerances, surface finish and alloy consistency matter most.

Available Grades

AISI 304, 316, 316L, 309, 310, 420, 904L, 301, 201

(High resolution in thickness and width, custom alloys available on request)

Thickness Range

0.05 mm – 10.00 mm

(Custom thicknesses above or below on request)

Width Range

5 mm – 2000 mm

(Bespoke widths including full-sheet sizes slit to your exact requirement)

Surface Finishes

2B

BA / Bright Annealed

1D / Hot Rolled

Polished / Brushed (on request)

Deburred, safe-edge, or fully rounded edges

Mechanical Properties (Typical)

Tensile strength: 650 – 1700 MPa, depending on grade and temper

High fatigue resistance for cyclic loads

Tight dimensional stability for premium components

Corrosion and salt-spray resistance for marine/industrial use

Dimensional Tolerances

Width tolerance: ±0.03 – ±0.10 mm

Thickness tolerance: per EN 10258 (precision strip standard)

Edge condition: slit, laser-cut, fully rounded for critical assemblies

Applications

Automotive high-precision brackets and trims

Aerospace structural components & brackets

Industrial automation and tooling

Medical device housings and lab equipment

Electronics chassis & high-end consumer goods

Marine subsea systems and offshore engineered parts

High-precision manufacturing and machining

Benefits

Premium European stainless-steel quality

Custom slit-to-width or coil-form available

Tight tolerances reduce scrap and improve assembly consistency

High repeatability for large-volume manufacturing

Designed for OEMs and system integrators with demanding specifications

Stainless Steel Slit Coils

Precision-slit stainless-steel coils engineered to your exact width, thickness and mechanical specifications.

Ideal for automotive systems, industrial fabrication, HVAC components, engineered assemblies and high-volume production.

Available Grades

AISI 304, 316, 316L, 309, 310, 301, 420, 430, 904L, 201

(316/316L/904L for corrosion resistance; 309/310 for high-temperature applications)

Thickness Range

0.30 mm – 12.00 mm

(precision gauges available on request)

Width Range

10 mm – 2000 mm

Slit to any custom width with tight tolerances.

Surface Finishes

2B

BA / Bright Annealed

1D / Hot Rolled

Polished / Brushed (on request)

Deburred, rounded or safe-edge options

Mechanical Properties (Typical)

Tensile strength: 550 – 1100 MPa (grade + temper dependent)

High dimensional stability

Excellent corrosion resistance

Consistent mechanical properties across full coil length

Dimensional Tolerances

Width tolerance: ±0.05 – ±0.20 mm

Thickness tolerance: per EN 10259 / EN 10258

Edge options: slit, deburred, rounded

Applications

Automotive components

Industrial fabrication & machine parts

HVAC systems

Electrical & cable routing systems

Brackets, clamps, hardware components

High-volume stamping, cutting & forming

Benefits

Tight, repeatable tolerances

High yield and minimal scrap

Fast European lead times

Custom mechanical properties available

CCTV, Telecom & Infrastructure Banding Systems

Robust stainless-steel banding and buckle systems engineered for secure mounting and long-term performance in outdoor, high-stress infrastructure applications.

Designed for CCTV camera poles, telecom towers, traffic signage, power utility networks, fiber-optic installations and industrial cable routing.

Available Grades

AISI 304, 316, 316L, 309, 310, 904L

(316/316L/904L for high-corrosion or coastal areas; 309/310 for elevated temperatures)

Width Compatibility

Standard band widths: 4.6 mm – 32 mm

(Custom widths available for large-scale infrastructure)

Mechanical & Performance Highlights

Tensile strength: 550 – 1100 MPa

Excellent corrosion resistance for outdoor, coastal & salt-spray environments

High vibration, UV and weathering resistance

Compatible with all industry-standard banding tools & buckle systems

Long service life with minimal maintenance

Applications

CCTV pole mounting & security camera brackets

Telecom towers, antenna mounts & fiber installations

Power utility poles, transformers & cable routing

Traffic signage, lighting poles & city infrastructure

Outdoor industrial enclosures & cable tray systems

Marine-adjacent infrastructure requiring corrosion protection

Benefits

Secure fastening for critical infrastructure

High load-bearing and tensile performance

Premium European stainless-steel durability

Full compatibility: banding + buckles + tooling

Optimized for telecom, electrical, marine, offshore & urban installations.

Need a Reliable Stainless-Steel Solution? Our Experts Are Ready to Help.

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.